Tyre Inflation and Costs

As shown below, periodical inspection of tyre pressure by a mobile service brings real and measurable financial benefits for your company.

In a fleet composed of 5 vehicles and an annual mileage of 120,000 km at an average fuel consumption of 30 l/100km the total annual fuel consumption amounts to 36,000 litres x 5 vehicles = 180,000 litres per year.

If the tyre pressure is too low, the fuel consumption increases by up to 2 litres per 100 km. Assuming we are able to save just 1 litre per 100 km, we save up to 6,000 litres of fuel per year. Maintaining the correct tyre pressure allows saving up to 2 litres per 100 km, which means 12,000 litres of fuel saved per year. When we multiply this number by today’s fuel price, the estimated savings in case of 5 units may reach between PLN 33,000 and PLN 60,000 on fuel alone, not taking into account the increased tyre wear caused by incorrect pressure.

If you start your cooperation with PNEUMASTER mobile service, the money you save will allow for purchasing economic class tyres and their comprehensive service, which guarantees complete safety and a good night sleep.

A tyre loses about 300 g of air during 6 months

25% of truck tyres are run constantly underinflated (pressure deficiency of between 0.5 and 1 bar per tyre)

10% of truck tyres are run severely underinflated (pressure deficiency above 1 bar per tyre)

Effects of underinflation:

- excessive fuel consumption which may reach up to 2 litres per 100 km, i.e. the fuel consumption is 5% higher per 100 km,

- lower tyre mileage,

- lower safety on the road (risk of tyre bursting, problems with grip),

- according to police statistics the cause of 40% of road accidents are problems with tyre pressure and 10% of fatalities are caused by underinflated tyres.

Tyre Replacement

In case of trucks the tyre replacement must be performed by qualified specialists, using specialist tools and liquids by following the appropriate rules, which allows avoiding damage to the tyre bead that would disqualify it from regeneration or further use.

Wheel Replacement

Replacing a wheel on the hub requires lifting and securing the vehicle in accordance with the safety regulations and other standards. Fitting and bolting a wheel (or twin wheels in particular) is a task that requires precision and must be performed using the torque specified by the manufacturers. It is crucial to correctly install the wheel on the hub and centre it, especially on the steering axle. A common error is to incorrectly clean and centre the wheel, which, despite balancing, causes the run out of wheels and destroys pins or tyre tread.

Rotating Tyres on a Rim

Rotating tyres on a rim, axle and position allows increasing mileage by up to 40% if done at the right time. It evens the tread wear and in consequence allows for more even regrooving of the tyres. It also allows the tyre crown to contact the road over its entire surface, which provides better traction and shorter braking distance.

Regrooving

Correct and professional regrooving restores the tread, prolongs the tyre’s service life, increases traction and allows using the tyre to its full potential, because the use of this process is taken into consideration during its design and production. So why doesn’t the manufacturer make tyres with a deeper tread? This question can only be answered by professionals and we will be happy to explain that to you during our visits or training sessions. Regrooving tyres is permitted by the Highway Code, with limitations which apply to certain types of vehicles.

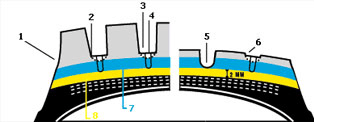

1 – Original tyre profile

2 – Bottom of the tread

3 – Tread wear indicator

4 – Regrooving depth indicator

5 – Regrooved profile

6 – Worn profile before regrooving

7 – Thickness of rubber for regrooving

8 – Thickness of rubber to be retained

Tread regrooving optimises the mileage by 15–30% depending on the situation and does not affect the ability of the carcass to undergo retreading. The rolling resistance of a regrooved tyre is reduced by 25% as compared to a new tyre, which results in lower fuel consumption.

Regrooving improves traction and thus affects safety, it also has a positive environmental impact (see the Environment Protection tab at the home page).

Repair

Repairs, phases of cold repair performed on the road:

- Inspection of damage to confirm the possibility to perform a repair, selection of materials,

- Cleaning and preparing for repair,

- Stabilising the belt near the puncture,

- Filling the puncture,

- Cleaning and preparing of the sealant – butyl,

- Application of the repair insert,

- Sealing and airtightness check.

The tyres are accepted for repair and the materials and repair technology are selected in accordance with a technical table, while considering the safety regulations.

NOTE! Not every kind of damage may be cold-repaired.

Balancing

Balancing is required to avoid unbalance of the wheel/tyre assembly. The active balancing technology used by our company allows for balancing while driving. The applied material adapts to the unbalancing type. This is especially important in case of wheels with hub caps, which are installed after balancing but still have an impact on the weight of rolling components. Active balancing is even more effective in vehicles driving on unpaved roads – the material accumulating in the thread does not allow for using traditional balancing with weights. In those two cases the benefits of using active balancing are unquestionable. Correct balancing in conjunction with correct centring and installation on the hub will optimise the tyre mileage by providing even wear, increase the driving comfort, decrease the wear of the steering system, suspension, pins and bearings and protect the electronic systems such as ABS or ASR against damage.

Retreading

Retreading is a process involving the removal of part of the tread that became worn during operation and replacing it with a new layer of tread. There are two types of retreading that are being used: cold retreading and hot retreading. The cold retreading method involves gluing a section of tread and its use is not advised by PNEUMASTER. PNEUMASTER uses a more expensive but better technology which uses hot processing of the tyre – the tread is not glued on, it is vulcanized, which means that the rubber is bound at atomic particle level. The method does not involve gluing and as such it allows to fully use the potential of the retreaded tyre without the risk of the tread becoming loose.

Retreading also allows for adapting the tread to new use conditions which provide 3 major benefits:

- financial benefit – the costs are considerably lower as compared to new tyres (the nominal price of a retreaded tyre is equal to about 60% of a new tyre price),

- economic benefit – the tyre gets a new life, it will be capable of reaching a mileage similar to that of a new tyre,

- environmental benefit – retreading allows for using the same carcass several times, depending on the mode of use.